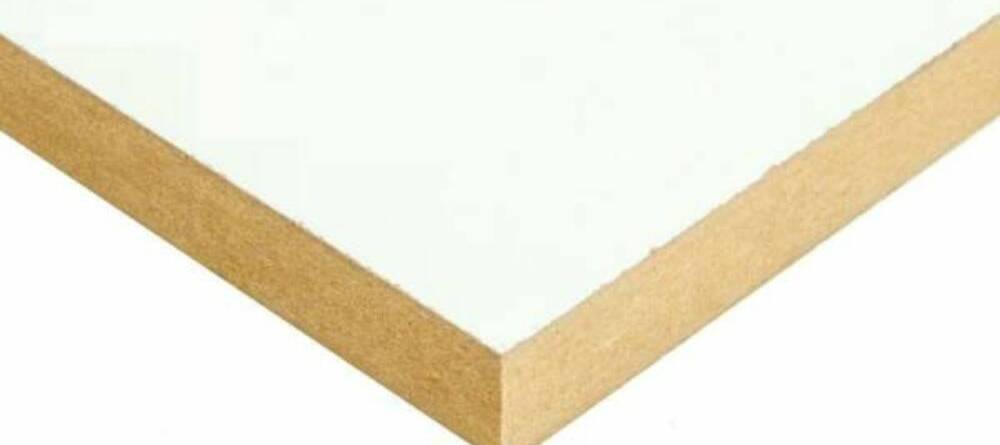

White melamine MDF is a type of wood widely used in furniture making, cabinetry, and various DIY projects. This material is manufactured by using synthetic resin to blend together the small wood fibres through high heat and pressure. The outcome of this process is a dense, stable, and uniform board. After that, a decorative layer of melamine is applied to the surface to give the object a shiny or matt, white surface with the desired level of gloss and hardness.

White Melamine MDF: Common Applications

1. Cabinetry and Shelving

White melamine MDF boards are preferable for kitchen and bathroom cabinets because their surfaces are easy to clean. White gives a clean and modern look and is often a preferred choice in modern home decor concepts.

2. Furniture Making

Melamine faced MDF is widely used for furniture, ranging from office desks to wardrobes and other furniture in the home and office. Its regular structure and desirable appearance make it suitable for the production of items that need to be carefully made.

3. Interior Decor

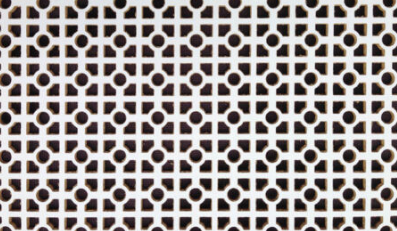

Many DIY creators often apply white melamine MDF sheets to manufacture decorative panels for walls, shelves, or room dividers. The easy machinability is beneficial for a large variety of design solutions.

4. Retail Fixtures

The melamine MDF is used to make display unit counters and shelving in retail merchandising stores. Made of stone, it is harder and can withstand heavy traffic and frequent cleaning.

How to Use White Melamine MDF for DIY Projects

White melamine MDF is a versatile material and not so difficult to work with if you follow a few simple guidelines.

1. Cutting and Shaping

Use the Right Tools: Use a saw blade made for cutting laminates to prevent chipping. The clay should be cut by a carbide-tipped blade with 80 teeth or more. For straight cuts, a table saw or a circular saw with a guide rail helps achieve the desired accuracy.

Prevent Chipping: Strips of masking tape can be placed on both sides of the board along the cut line to avoid chipping. Lift the tape, and make sure to remove it after you have cut it. Pass the board into the saw steadily and slowly for controlling and chip-free cuts.

2. Edge Finishing

Use adhesive tapes made of melamine in order to hide raw, exposed edges. This tape has an adhesive that can be activated by heating. Apply the tape by using a household iron set at medium settings. Once the tape is cool, use a utility knife or specialised edge trimmer to cut off any extra. Sand edges with fine-grit sandpaper to remove sharpness.

3. Fastening

Pre-Drill Holes: Make pilot holes so as to prevent saw cutting of MDF when screwing in screws. The pilot hole should be made to be a slightly smaller size than the screw to be used. Ensure that the screws used have deeper threads to fasten the MDF material effectively.

Deburr the drilled holes by chamfering them so that they are level with or slightly below the screw heads. The material used should be tightened using small turns of the screw head so as not to over-tighten, hence leading to stripping of the material. Over-tightening will cause the MDF to lose its grip and damage it at the same time.

4. Joining Techniques

Stronger Joints: Choose dowels for extra-strong joints. They provide added support and guidance during the joining process. Pocket screws are another good way, especially if you’re looking for right-angle joints with plenty of strength.

Choose a melamine-compatible glue that is manufactured for melamine boards. Common glue is not appropriate and will not stick. Apply glue to the joints, and then fix them with clamps while the glue is drying.

5. Maintenance

Regular Cleaning: Clean the surfaces periodically with a dusting broom to remove debris. Clean it with a soft cloth using damp water. It is advisable to steer clear of abrasive pads as well as cleaners that can scratch the surface.

Stain Removal: For stains that cannot be removed with plain water, a mild detergent solution should be applied. Do not also use strong cleaners that will eat the melamine coating. Attend to spillages right away to avoid discolouration and degradation of the surface.

6. Finishing Touches

Painting and Sealing: If you want to paint melamine MDF, you should apply a primer designed for use on non-porous natural surfaces. This works to make the paint stronger. Use quality acrylic and apply as many thin layers as necessary for a smooth finish. Applying a clear sealant or varnish over the paint is optional but may add durability.

7. Safety Precautions

Protect Yourself: Wear a dust mask to prevent inhaling small particles of dust resulting from cutting or sanding MDF. Wear goggles to avoid injuries caused by flying particles. Wear noise-cancelling headphones when power tools are being operated.

Ventilation: Work in a Well-Ventilated Area: It is also advisable to keep the working environment well-ventilated, especially when cutting or sanding, and this helps to reduce the buildup of dust and minimise the risk of dust inhalation.

If you adopt these tips, it is possible to do your projects and have a high-quality finished product with white melamine MDF. These guidelines should prove helpful for those who use wood in making items such as custom furniture or cabinets or those who want to design decorative pieces.

Reasons to Choose White Melamine MDF Sheets

The application of white melamine MDF sheets has multiple advantages for professional carpenters and DIY lovers.

1. Cost-effective

The price of white melamine MDF is comparatively cheaper than white solid wood, plywood and other wood composites. This makes it a very good option for low-budget projects without the need to sacrifice quality.

2. Very convenient and easy to work with

Melamine-faced MDF is consistently dense and has a uniform surface that cuts, drills and moulds easily. It is also easy to handle, especially when it comes to DIY projects.

3. Durable and long-lasting

The melamine coating gives MDF a very hard and durable surface that resists scratching and staining as well as moisture. This is why white melamine MDF boards are perfect for practical parts of the home like the kitchen and the bathroom.

4. Low maintenance

White melamine MDF sheet is easy to clean and maintain. The non-porous surface has no pores to absorb moisture and spills and is only cleaned with a damp cloth. This passive and easy-care advantage is valuable for both private and business buildings.

5. Aesthetic appeal

Melamine is a white-finished MDF with a modern and sleek outlook for any project. It is very versatile, can easily be combined with different design styles, and often gives the design a minimalist look.

Read More: Top Advantages Of Utilising Mdf Moisture Resistant Building Materials

To Sum Up

White melamine MDF is a versatile material used for numerous purposes in DIY projects. Its variety, affordability, and simplicity in application make it ideal for new and experienced carpenters. White melamine MDF sheets are a practical and versatile material that is well-suited for the fabrication of cabinets, furniture, and decorative items and meets various aesthetic or functional requirements. Contact Builders Merchant Ltd for premium White Melamine MDF and other building material supplies for your next construction project.